charpy impact test results analysis|charpy impact test calculator : wholesalers Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact . Resultado da O resultado final da partida entre Novorizontino-SP x Vitória é o 1 - 2. O jogo foi jogado em 12/11/2023 como parte de Brasileirão Série B. Aqui na Oddspedia você pode encontrar as odds do pré-jogo do Novorizontino-SP x Vitória, estatísticas das partidas, todos os momentos importantes, .

{plog:ftitle_list}

Stop taking fidaxomicin and get emergency medical help if you have signs of an allergic reaction: hives, rash, itching; difficult breathing; swelling of your face, lips, tongue, or throat. Fidaxomicin may cause serious side . Ver mais

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .Understanding Charpy Impact Test results is essential for evaluating a material’s performance under impact loads and ensuring that it meets industry-specific standards—a critical aspect of material testing and design assessment.

Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

This page explains basic knowledge of the Charpy impact test and test pieces and how to evaluate the test results. It also introduces problems in evaluating test results and in conventional measurement methods, as well as a solution .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of .

Once researchers found that impact-test results improved their understanding of the performance of materials in service, they began to focus their attention on reducing the scatter .

The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic . From this analysis, it results that the constitutive model of multilinear material introduced in the simulation of the Charpy test gave results closer to reality for the more fragile materials. For the most ductile material (PA6m), with a high yield value, the model had a much higher impact energy absorption than the actual one, which would .This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A . Computational analysis of Charpy impact test using interface elements. Trans. JWRI, 2001, Vol.30, 97-102. [5] ANSYS 12.1 Software Tutorials. Title: Finite Element Modelling for Numerical Simulation of Charpy Impact Test on Materials

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

1000n tensile test machine compression tester

charpy impact tester

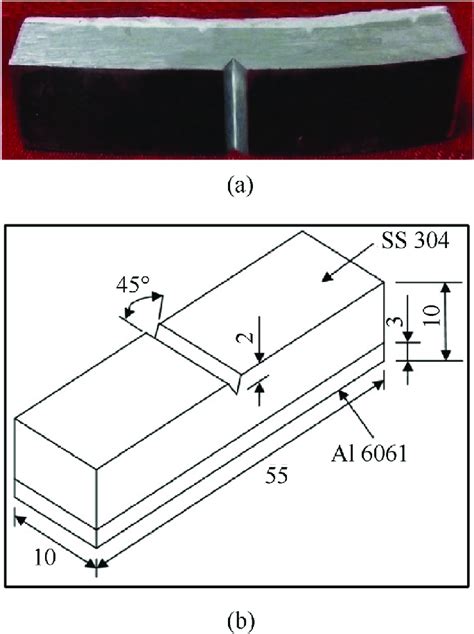

Splett JD, McCowan CN, Iyer H and Wang C Computing Uncertainty for Charpy Impact Machine Test Results NIST-SP 960-18 (2008) Siewert TA Evaluation Specimens for Izod Impact Machines (SRM 2115): Report of Analysis NIST SP 260-164 (2007) McCowan CN and Splett JD Analysis of Charpy Impact Verification Data: 1993-2003 Journal of ASTM International . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

Throughout this experiment the impact test analysis of the steel specimens has been properly conducted. It has been observed that ductile materials under certain conditions display brittleness. . 𝛽 = Maximum angle of pendulum after release The results of the Charpy impact test indicate the energy absorbed by the material specimens .The Charpy v-notch test remains an important quality assurance assessment quantifying a material’s resistance to sudden fracture from impacts.. Charpy impact test procedures, results analysis, and key advantages of this method versus alternatives like the Izod impact test. The standardized test measures the energy absorbed fracturing a notched specimen using a .Charpy Test. The results of the Charpy impact tests at ambient temperature for electrolytically pre-charged X65 specimens are summarized in Table 2. . Results of LECO analysis showed that an average of 1.4 ppm total hydrogen in X65 was seen for specimens pre-charged at 2.5 mA/cm 2 for 1 h. Further increase of charging current density and time .

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.

In this paper, instrumented impact test results obtained using V-notch and precracked Charpy specimens of AISI 308 weld and AISI 316 stainless steels are analysed for determining the plastic η-factor for three-point bend specimens used in J-integral evaluation. Tested 316 stainless steel specimens were in various thermal aging/cold-work conditions whereas 308 weld specimens . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This paper investigates using the Charpy impact test as a certification test for a production batch. First, the best conditions for surface finishing and then the Charpy impact test results from one reference batch (defect-free) and one defective batch were compared. Hereinbelow are the main conclusions.

Test Results and Analysis. Charpy test results, expressed as energy absorbed or fracture toughness, are often presented graphically in a Charpy impact energy curve. This visual representation offers insights into the toughness properties of the material. Figure 2 - Example of test results Charpy Test Advantages

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . Upgrade .A statistical analysis of the Charpy V-Notch toughness test results was conducted based on sixty-nine A588 and A572 steel plates from four of the six mills who participated in the survey. The study was conducted for three test temperatures (0°F, 40°F, and 70°F), four thickness groups (T1 to T4, defined later), and two steel grades (A572 and .

charpy impact test sample dimensions

Aluminum alloy wheels are used worldwide in both the warmest and coldest temperatures. This study was conducted to investigate the impact resistance of aluminum alloy wheels produced by the low-pressure die casting process in real-life conditions. The V-notched Charpy impact test specimens were extracted from T6 heat-treated A356 aluminum alloy .Charpy impact test results can be shown in Table 2. The thicker specimens show better impact properties at room tem- perature conditions than thinner specimens, according to these results. . ASTM D256 and its equivalent ISO 180 recommend Izod as the standard testing method over Charpy for low-velocity impact testing (Raj et al. Citation 2021). For high-velocity impact testing, the damaging surface is more localised, so the structural response is less important, and therefore equal dimensioning is not relevant.

Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead . The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test .To further analyze the influence of the specimen width on the Charpy impact test results, it is observed that there exists a good linear relationship between the specimen width and the corresponding maximum force for the same sample geometry. . El Alami, M., Laazizi, A. & Fri, K. Numerical analysis EF of resilience impact test behavior for . Specimens with different widths and side grooves are tested. The finite element model of Charpy impact was established by ABAQUS software. Use test results and simulation results to verify each other.

In this paper, instrumented impact test results obtained using V-notch and precracked Charpy specimens of AISI 308 weld and AISI 316 stainless steels are analysed for determining the plastic . Charpy impact test is a low cost but reliable test that breaks a notch specimen under impact loading using a hammer, and evaluates the amount of energy consumed during breakage . Several researchers have focused their work, both experimental and numerical, in the area of impact testing to analyse different materials behavior.

textile fabric tensile testing machine price

Derpixon 's New Videos. Eri-Chan's Home Workout! - Derpixon || Legendado em PT-BR e ENG. Eri-Chan's Home Workout! Watch the best Derpixon videos in the world for free .

charpy impact test results analysis|charpy impact test calculator